Required to have a backfire flame arrestor is a critical safety measure implemented in various industries and applications to prevent the spread of flames and explosions. These devices play a crucial role in mitigating risks associated with backfires, ensuring the safety of personnel, equipment, and the environment.

Backfire flame arrestors are designed to extinguish flames and prevent their propagation through a series of flame-quenching elements. They are commonly used in internal combustion engines, fuel systems, and other applications where flammable gases or vapors are present.

Understanding Backfire Flame Arrestors

Backfire flame arrestors are critical safety devices designed to prevent the propagation of flames and explosions in various industries and applications. These devices are essential for safeguarding personnel, equipment, and facilities from the hazardous effects of backfires.

Types of Backfire Flame Arrestors

- Passive Flame Arrestors:These arrestors rely on physical barriers to quench flames, such as metal screens or ceramic honeycomb structures.

- Active Flame Arrestors:These arrestors utilize sensors and actuators to detect and suppress backfires, providing faster response times and increased safety.

Applications of Backfire Flame Arrestors

- Gas turbines

- Internal combustion engines

- Fuel storage and handling systems

- Chemical processing plants

Benefits of Using Backfire Flame Arrestors

Safety Enhancement

Backfire flame arrestors significantly reduce the risk of fires and explosions by preventing the propagation of flames through pipelines or equipment. They provide a physical barrier that quenches flames, protecting personnel and property.

Flame Suppression

These devices are designed to suppress backfires by absorbing heat and cooling the combustion gases. By interrupting the flame path, they prevent the spread of flames and minimize the potential for explosions.

Case Study: Explosion Prevention in Gas Turbines

A gas turbine power plant experienced a backfire during startup. The backfire flame arrestor installed on the turbine’s exhaust system successfully extinguished the flames, preventing a catastrophic explosion and protecting the plant from significant damage.

Design and Construction of Backfire Flame Arrestors

Design Principles

Backfire flame arrestors are designed to provide a high surface area for heat absorption while minimizing pressure drop. They are typically constructed with multiple layers of metal screens or ceramic honeycomb structures.

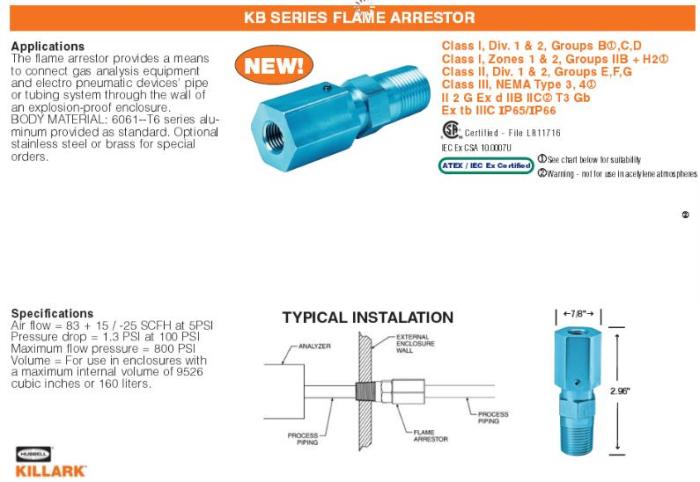

Materials

- Stainless Steel:Resistant to corrosion and high temperatures

- Aluminum:Lightweight and durable

- Ceramic:High thermal conductivity and flame resistance

Specifications

| Parameter | Typical Range |

|---|---|

| Nominal Pipe Size | 1/2″ to 12″ |

| Pressure Rating | Up to 1000 psig |

| Temperature Rating | Up to 2000°F |

Installation and Maintenance of Backfire Flame Arrestors: Required To Have A Backfire Flame Arrestor

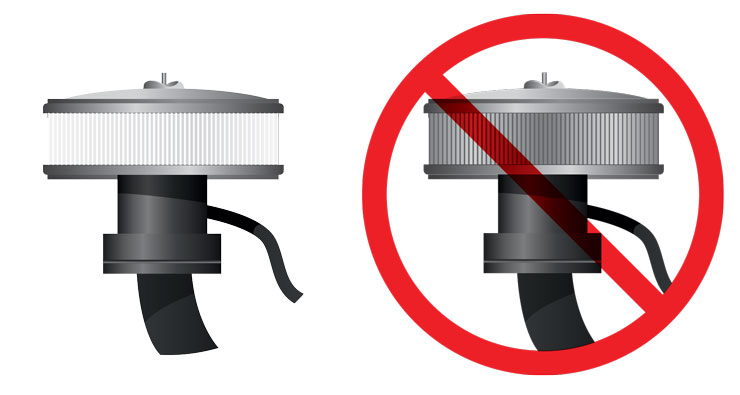

Installation Procedures

- Install the flame arrestor in the correct orientation, as specified by the manufacturer.

- Ensure proper alignment and secure fastening.

- Provide adequate clearance for maintenance and inspection.

Maintenance Schedule, Required to have a backfire flame arrestor

| Frequency | Task |

|---|---|

| Quarterly | Visual inspection for damage or corrosion |

| Annually | Removal and cleaning of flame arrestor elements |

| As needed | Replacement of damaged or worn components |

Regulations and Standards for Backfire Flame Arrestors

Governing Bodies

- National Fire Protection Association (NFPA)

- Occupational Safety and Health Administration (OSHA)

Relevant Standards

- NFPA 30: Flammable and Combustible Liquids Code

- OSHA 29 CFR 1910.263(h): Control of Flammable and Combustible Liquids

Key Requirements

| Regulation | Key Requirement |

|---|---|

| NFPA 30 | Backfire flame arrestors required for fuel storage tanks and dispensing systems |

| OSHA 29 CFR 1910.263(h) | Backfire flame arrestors required for internal combustion engines |

FAQ

What is the purpose of a backfire flame arrestor?

A backfire flame arrestor is designed to prevent the spread of flames and explosions by extinguishing flames as they pass through a series of flame-quenching elements.

Where are backfire flame arrestors commonly used?

Backfire flame arrestors are commonly used in internal combustion engines, fuel systems, and other applications where flammable gases or vapors are present.

How do backfire flame arrestors work?

Backfire flame arrestors work by creating a series of small passages or channels that extinguish flames as they pass through. These passages or channels are designed to disrupt the flame front and prevent its propagation.